Category

- Abrasives

- Adhesives & Sealants

- Automotive

- Bearings & Transmissions

- Cabinets & Racking

- Calipers & Gauges

- Catering Equipment & Supplies

- Cleaning & Hygiene

- Collets & Toolposts

- Computers & Accessories

- Counterboring & Spot Facing

- Cutting Tools

- Bandsaws & Hacksaws

- Countersinking

- Deburring

- Hole Making

- Milling

- Ball Nose

- Carbide B/N End Mills – Long Series

- Carbide B/N End Mills – Regular Series

- Carbide B/N End Mills – Short Series

- Carbide B/N Slot Drills – Long Series

- Carbide B/N Slot Drills – Regular Series

- HSS B/N Slot Drills – Long Series

- HSS B/N Slot Drills – Short Series

- HSS-Co. B/N Slot Drills – Long Series

- HSS-Co. B/N Slot Drills – Short Series

- Bore Milling

- End Mills

- Carbide Double Ended End Mills – Regular Series

- Carbide End Mills – Long Series

- Carbide End Mills – Regular Series

- Carbide End Mills – Short Series

- HSS End Mills – Long Series

- HSS End Mills – Short Series

- HSS-Co. End Mills – Long Series

- HSS-Co. End Mills – Regular Series

- HSS-E PM End Mills – Regular Series

- Indexable Bodies

- Key & Slot Cutters

- Milling Inserts

- Roughing/Ripper Cutters

- Slot Drills

- Carbide Slot Drills – Double Ended

- Carbide Slot Drills – Long Series

- Carbide Slot Drills – Regular Series

- Carbide Slot Drills – Short Series

- HSS Slot Drills – Long Series

- HSS Slot Drills – Short Series

- HSS-Co. Slot Drills – Long Series

- HSS-Co. Slot Drills – Regular Series

- HSS-Co. Slot Drills – Short Series

- Slot Drill Cutter Sets

- Special Geometry Cutters

- Throwaway Cutters

- Ball Nose

- Part off & Grooving

- Reamers

- Reference/Data Books

- Threading

- Die nuts

- Dies

- Indexable

- Tapping Hand

- BA ISO529 HSS-GT Taps

- BSF ISO529 HSS-GT Taps

- BSPF ISO529 HSS-GT Taps

- BSPT ISO529 HSS-GT Taps

- BSW ISO529 HSS-GT Taps

- Combination Drill/Taps

- Left Hand ISO529 HSS-GT Taps

- Metric Coarse ISO529 HSS-GT Taps

- Metric Fine ISO529 HSS-GT Taps

- Metric ISO529 HSS-GT Threading Sets

- NPSF ISO529 HSS-GT Taps

- NPT ISO529 HSS-GT Taps

- NPTF ISO529 HSS-GT Taps

- Tap Wrenches

- UNC ISO529 HSS-GT Taps

- UNF ISO529 HSS-GT Taps

- Tapping Production

- Thread Chasers

- Turning

- Display Material

- Fasteners

- Fluid & Water Control

- Fluid Power

- Furniture

- Hand Tools

- Building & Construction

- Carpenters & Joiners

- Auger; Forstner & Flat Bits

- Bradawls; Gimlets & Tacklifters

- Chalk Lines

- Hand Drills & Braces

- Hole Cutters

- Marking & Cutting Gauges

- Mitre Blocks & Bench Hooks

- Pincers

- Planes

- Saws – Coping; Fret & Flexisaws

- Saws – Gents; Dovetail & Tenon

- Saws – Hand & Mitre

- Squares; Rules & Bevels

- Surface Forming Tools

- Wood Chisels

- Wood Turning & Carving Tools

- Clamps

- Cutting & Sawing

- Cycle Tools

- Decorators

- Electrical

- Engineers Tools

- Gardeners & Contractors

- Keys & Drivers

- Measuring

- Non Sparking Tools

- Pliers & Grips

- Plumbing & Pipe Tools

- Riveters

- Screwdriver Bits

- Screwdrivers

- Screwdrivers – Cabinet Handle

- Screwdrivers – Electronics & Mini

- Screwdrivers – Fluted Handle

- Screwdrivers – Hi-Grip/Mechanics Style Handle

- Screwdrivers – Insulated Handle

- Screwdrivers – Offset/Double Ended

- Screwdrivers – Precision/Jewellers

- Screwdrivers – Protorq/Magnum Style Handle

- Screwdrivers – Spiral Ratchet/Yankee

- Sheet Metal Working

- Sockets (Hand)

- Sockets (Impact)

- Spanners & Wrenches

- Stencils & Engraving

- Striking Tools

- Tool Kits & Multi Tools

- Torque Tools

- Vices

- Lubricants & Chemicals

- Anti Seize Lubricants

- Chain; Drive & Rope Lubricants

- Corrosion Preventatives & Welders Anti-Spatter

- Food Industry Lubricants & Greases

- Greases

- Grinding Fluids

- Hot Dip Coatings

- Industrial Cleaners & Solvents

- Leak Detectors; Flawfinders & Freezer Sprays

- Lubricating and Penetrating Oils

- Marker Paints & Pens

- Metal Cutting Coolants

- Mould Release Agents

- Paints & Primers

- Tapping & Drilling Lubricants

- Water Displacing & Maintenance Oils

- Materials & Maintenance

- Measuring & Test Equipment

- Co-Ordinate Measuring Machines

- Electrical Measuring & Testing Equipment

- Environment Gauges

- Inspection Workholding

- Mechanical Gauges

- Non-Mechanical Gauges

- Optical Equipment

- SPC & Digital Readout Equipment

- Spring Calipers & Spring Dividers

- Surface/Hardness Testers

- Test Gauges & Accessories

- Weigh Scales

- Office Supplies & Stationery

- Packaging

- Pads & Accounts

- Personal Protection

- Clothing & Workwear

- Eye Protection

- Footwear

- Hand Protection

- Gloves – Cold Resistant

- Gloves – Cotton

- Gloves – Cowhide

- Gloves – Disposable

- Gloves – Extra Grip

- Gloves – Goatskin

- Gloves – Latex

- Gloves – Leather

- Gloves – Mixed Fibre

- Gloves – Nitrile

- Gloves – Polkadot

- Gloves – Polyurethane

- Gloves – PVC

- Gloves – Rigger

- Gloves – Stockinette

- Gloves – Terry Towelling

- Gloves – Vinyl

- Gloves – Welders Gauntlets

- Head & Face Protection

- Hearing Protection

- Knee & Elbow Pads

- Personal Protection Kits

- Respiratory Protection

- Piston & Valve Tools

- Power Tools

- Site Safety

- Spindle Nose & Workholding

- Steps & Access Equipment

- Storage & Handling

Blog

Relaunch Promotion

Product Showcase

10.0mm 4FL STANDARD CARBIDE END MILL

Rp958.000

Kennedy Carbide Micrograin Plain Shank Milling Cutters, 4 Flute: Regular Series, Metric

4 Flute: Regular Series – Metric

Centre cutting as standard. For maximum strength when milling harder materials where rapid swarf removal is not needed. 4 flute milling cutters have one of the strongest tooth structures available in solid cutters. Manufactured to Works Standards.

Metric Tolerances

Diameter: Over 1.00 ~ up to 6.00. Tolerance: +0.000, -0.050.

Diameter: Over 6.00 ~ up to 25.00. Tolerance: +0.000, -0.080.

Out of stock

SKU : KEN1616200K

Kennedy Carbide Micrograin Plain Shank Milling Cutters, 4 Flute: Regular Series, Metric

4 Flute: Regular Series – Metric

Centre cutting as standard. For maximum strength when milling harder materials where rapid swarf removal is not needed. 4 flute milling cutters have one of the strongest tooth structures available in solid cutters. Manufactured to Works Standards.

Metric Tolerances

Diameter: Over 1.00 ~ up to 6.00. Tolerance: +0.000, -0.050.

Diameter: Over 6.00 ~ up to 25.00. Tolerance: +0.000, -0.080.

Specification :

Brand : Kennedy Industrial

Diameter (mm) : 10.00 | mm

eCl@ss Code : 21010500

Flute Length (mm) : 22.0

Overall Length (mm) : 70

Overall Weight : 0.1

Shank Diameter (mm) : 10.0

Supplier Part No. : –

UNSPSC Code : 23241614

Weight each : 100g

| Weight | 1 kg |

|---|

Related products

-

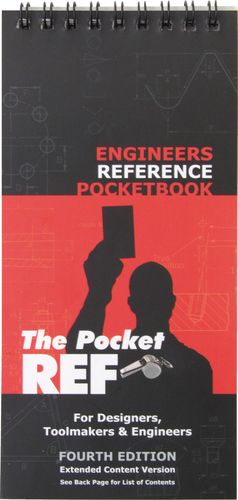

THE REF FLIPCHARTS 4TH EDITION WIRORead more

Engineers Reference Data Charts

Now with 38 pages of engineering data. Each page coated with an gloss lamination to protect against the dirt and grease encountered in workshop conditions.

Contents:

⢠Basic forms of heat treatment

Colour charts for tempering and for hardening & forging.

⢠Material groups

Colour coded machineability chart and hardness listing.

⢠Tensile strength and hardness

Shore hardness and equivalent tensile strengths and conversions included.

⢠Lubricant selection

Colour coded materials chart and dilution guidelines.

⢠Hole and shaft tolerances

H7-e8 tolerances for counterbores included.

⢠Metric screw and hole sizes

⢠Thread notation

Explains terminology used to define thread characteristics.

⢠Standard thread forms;

Sequenced logically, tapping and clearance sizes integrated into single chart and colour highlighted for quick reference. Includes special metric pitches & NPT, distinctions made between ‘Rp’ and ‘G’ series BSP. ISO 529 pitch form diagrams shown. Now also lists tapping and clearance drill sizes for fluteless tap.

⢠Dimensions of common shank types

Now includes screwed shank, Weldon, DIN Taper, BT Taper, ISO Taper in addition to Morse taper shank details.

⢠Standards for engineering drawings

Comprehensive listing including contemporary listings and illustrations.

⢠Abbreviations used in engineering drawings

⢠Common CNC codes

Comprehensive listing including contemporary listings.

⢠Axis nomenclature for machine tools

Newly added page explaining the use of letter addresses to define directional motion.

⢠Trigonometry formulae

Colour coded CAD produced illustrations for quick reference.

⢠Sines and Cosines

Calculated to six decimal places with colour coded axes for quick reference.

⢠Tangents and Cotangents

Calculated to six decimal places with colour coded axes for quick reference.

⢠Co-ordinates for equally pitched holes

Clear and easy to read CAD produced diagrams.

⢠Bending allowances for malleable materials

Listed as metric radius and thickness with nearest equivalent SWG given for guidance. Clear and easy to read CAD produced diagrams.

⢠Cutting speed calculator

Gives required RPM for known cutter diameters and cutting speeds.

⢠Standard drill size conversions;

No & letter sizes integrated into a single chart, standard sizes are highlighted in bold text, size range extended from 25.25mm up to 32.50mm. All inch-fractional sizes converted to mm equivalent as well as inch-decimal and Morse Taper shank sizes are indicated against drill diameter ranges.

⢠Abbreviations and formulaes

Definitions of standard meanings with specific attention given to turning, milling and drilling.

Comprehensive list of commonly used abbreviations.

⢠Weight and measure systems, useful conversions and constants

A comprehensive listing of contemporary and old systems, along with the necessary conversion formulae. -

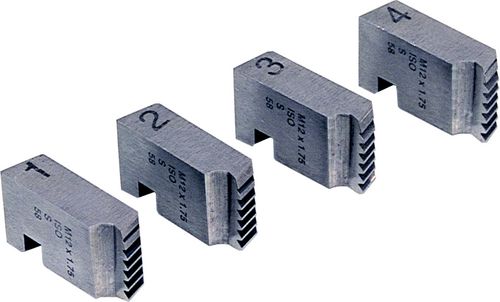

M4x0.70mm CHASER DIE 6mmD/HD TYPE S20Read more

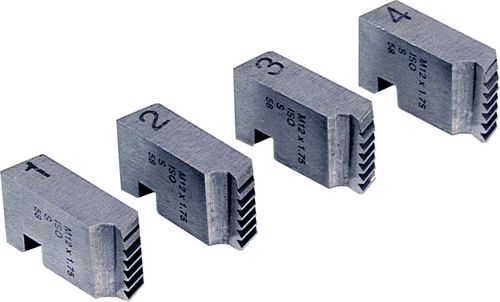

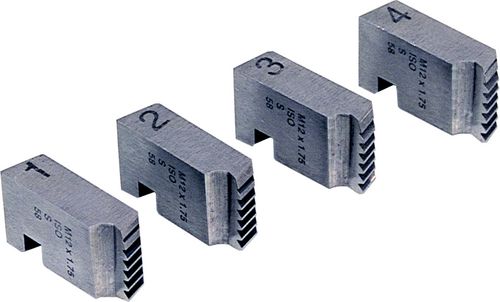

Coventry Type Chaser Dies – ISO Metric: Throat Angle S20

Cutting takes place only on the throat and the first full tooth; the remaining threads are above centre height and act as a nut, ensuring accurate pitch. Ideal for batch work or continuous production of threaded steel bar. Coventry dies are not interchangeable. An original set of new dies must always be used together. When taken from the diehead the set of dies should be retained in its box until required again.

Throat Angles

20° for general work and soft steels – supplied as standard.

33° âBâ type for cutting brass, available on request.Grinding Dies

Only two angles are ground on Coventry dies, the throat angle and the rake angle and in the particular case of Holozone dies only the throat angle is ground. All dies in a set must be ground on the throat at the same time and since they cannot be accurately ground by hand, a die grinding fixture must be used.Marking & Materials

Each die is marked with: diameter, pitch, type of die and gauge number. Non-standard or special dies are marked with an SD number which should be quoted when re-ordering. When a set of dies has been re-ground several times by grinding the throat angle, the height of the cutting edge rises above centre. This condition must be rectified by grinding the rake angle until the die height is correct according to the number shown on the die. -

M24x3.00mm CHASER DIE 32mm D/HD TYPE S20Read more

Coventry Type Chaser Dies – ISO Metric: Throat Angle S20

Cutting takes place only on the throat and the first full tooth; the remaining threads are above centre height and act as a nut, ensuring accurate pitch. Ideal for batch work or continuous production of threaded steel bar. Coventry dies are not interchangeable. An original set of new dies must always be used together. When taken from the diehead the set of dies should be retained in its box until required again.

Throat Angles

20° for general work and soft steels – supplied as standard.

33° âBâ type for cutting brass, available on request.Grinding Dies

Only two angles are ground on Coventry dies, the throat angle and the rake angle and in the particular case of Holozone dies only the throat angle is ground. All dies in a set must be ground on the throat at the same time and since they cannot be accurately ground by hand, a die grinding fixture must be used.Marking & Materials

Each die is marked with: diameter, pitch, type of die and gauge number. Non-standard or special dies are marked with an SD number which should be quoted when re-ordering. When a set of dies has been re-ground several times by grinding the throat angle, the height of the cutting edge rises above centre. This condition must be rectified by grinding the rake angle until the die height is correct according to the number shown on the die. -

M30x3.50mm CHASER DIE 32mm D/HD TYPE S20Read more

Coventry Type Chaser Dies – ISO Metric: Throat Angle S20

Cutting takes place only on the throat and the first full tooth; the remaining threads are above centre height and act as a nut, ensuring accurate pitch. Ideal for batch work or continuous production of threaded steel bar. Coventry dies are not interchangeable. An original set of new dies must always be used together. When taken from the diehead the set of dies should be retained in its box until required again.

Throat Angles

20° for general work and soft steels – supplied as standard.

33° âBâ type for cutting brass, available on request.Grinding Dies

Only two angles are ground on Coventry dies, the throat angle and the rake angle and in the particular case of Holozone dies only the throat angle is ground. All dies in a set must be ground on the throat at the same time and since they cannot be accurately ground by hand, a die grinding fixture must be used.Marking & Materials

Each die is marked with: diameter, pitch, type of die and gauge number. Non-standard or special dies are marked with an SD number which should be quoted when re-ordering. When a set of dies has been re-ground several times by grinding the throat angle, the height of the cutting edge rises above centre. This condition must be rectified by grinding the rake angle until the die height is correct according to the number shown on the die.