Category

- Abrasives

- Adhesives & Sealants

- Automotive

- Bearings & Transmissions

- Cabinets & Racking

- Calipers & Gauges

- Catering Equipment & Supplies

- Cleaning & Hygiene

- Collets & Toolposts

- Computers & Accessories

- Counterboring & Spot Facing

- Cutting Tools

- Bandsaws & Hacksaws

- Countersinking

- Deburring

- Hole Making

- Milling

- Ball Nose

- Carbide B/N End Mills – Long Series

- Carbide B/N End Mills – Regular Series

- Carbide B/N End Mills – Short Series

- Carbide B/N Slot Drills – Long Series

- Carbide B/N Slot Drills – Regular Series

- HSS B/N Slot Drills – Long Series

- HSS B/N Slot Drills – Short Series

- HSS-Co. B/N Slot Drills – Long Series

- HSS-Co. B/N Slot Drills – Short Series

- Bore Milling

- End Mills

- Carbide Double Ended End Mills – Regular Series

- Carbide End Mills – Long Series

- Carbide End Mills – Regular Series

- Carbide End Mills – Short Series

- HSS End Mills – Long Series

- HSS End Mills – Short Series

- HSS-Co. End Mills – Long Series

- HSS-Co. End Mills – Regular Series

- HSS-E PM End Mills – Regular Series

- Indexable Bodies

- Key & Slot Cutters

- Milling Inserts

- Roughing/Ripper Cutters

- Slot Drills

- Carbide Slot Drills – Double Ended

- Carbide Slot Drills – Long Series

- Carbide Slot Drills – Regular Series

- Carbide Slot Drills – Short Series

- HSS Slot Drills – Long Series

- HSS Slot Drills – Short Series

- HSS-Co. Slot Drills – Long Series

- HSS-Co. Slot Drills – Regular Series

- HSS-Co. Slot Drills – Short Series

- Slot Drill Cutter Sets

- Special Geometry Cutters

- Throwaway Cutters

- Ball Nose

- Part off & Grooving

- Reamers

- Reference/Data Books

- Threading

- Die nuts

- Dies

- Indexable

- Tapping Hand

- BA ISO529 HSS-GT Taps

- BSF ISO529 HSS-GT Taps

- BSPF ISO529 HSS-GT Taps

- BSPT ISO529 HSS-GT Taps

- BSW ISO529 HSS-GT Taps

- Combination Drill/Taps

- Left Hand ISO529 HSS-GT Taps

- Metric Coarse ISO529 HSS-GT Taps

- Metric Fine ISO529 HSS-GT Taps

- Metric ISO529 HSS-GT Threading Sets

- NPSF ISO529 HSS-GT Taps

- NPT ISO529 HSS-GT Taps

- NPTF ISO529 HSS-GT Taps

- Tap Wrenches

- UNC ISO529 HSS-GT Taps

- UNF ISO529 HSS-GT Taps

- Tapping Production

- Thread Chasers

- Turning

- Display Material

- Fasteners

- Fluid & Water Control

- Fluid Power

- Furniture

- Hand Tools

- Building & Construction

- Carpenters & Joiners

- Auger; Forstner & Flat Bits

- Bradawls; Gimlets & Tacklifters

- Chalk Lines

- Hand Drills & Braces

- Hole Cutters

- Marking & Cutting Gauges

- Mitre Blocks & Bench Hooks

- Pincers

- Planes

- Saws – Coping; Fret & Flexisaws

- Saws – Gents; Dovetail & Tenon

- Saws – Hand & Mitre

- Squares; Rules & Bevels

- Surface Forming Tools

- Wood Chisels

- Wood Turning & Carving Tools

- Clamps

- Cutting & Sawing

- Cycle Tools

- Decorators

- Electrical

- Engineers Tools

- Gardeners & Contractors

- Keys & Drivers

- Measuring

- Non Sparking Tools

- Pliers & Grips

- Plumbing & Pipe Tools

- Riveters

- Screwdriver Bits

- Screwdrivers

- Screwdrivers – Cabinet Handle

- Screwdrivers – Electronics & Mini

- Screwdrivers – Fluted Handle

- Screwdrivers – Hi-Grip/Mechanics Style Handle

- Screwdrivers – Insulated Handle

- Screwdrivers – Offset/Double Ended

- Screwdrivers – Precision/Jewellers

- Screwdrivers – Protorq/Magnum Style Handle

- Screwdrivers – Spiral Ratchet/Yankee

- Sheet Metal Working

- Sockets (Hand)

- Sockets (Impact)

- Spanners & Wrenches

- Stencils & Engraving

- Striking Tools

- Tool Kits & Multi Tools

- Torque Tools

- Vices

- Lubricants & Chemicals

- Anti Seize Lubricants

- Chain; Drive & Rope Lubricants

- Corrosion Preventatives & Welders Anti-Spatter

- Food Industry Lubricants & Greases

- Greases

- Grinding Fluids

- Hot Dip Coatings

- Industrial Cleaners & Solvents

- Leak Detectors; Flawfinders & Freezer Sprays

- Lubricating and Penetrating Oils

- Marker Paints & Pens

- Metal Cutting Coolants

- Mould Release Agents

- Paints & Primers

- Tapping & Drilling Lubricants

- Water Displacing & Maintenance Oils

- Materials & Maintenance

- Measuring & Test Equipment

- Co-Ordinate Measuring Machines

- Electrical Measuring & Testing Equipment

- Environment Gauges

- Inspection Workholding

- Mechanical Gauges

- Non-Mechanical Gauges

- Optical Equipment

- SPC & Digital Readout Equipment

- Spring Calipers & Spring Dividers

- Surface/Hardness Testers

- Test Gauges & Accessories

- Weigh Scales

- Office Supplies & Stationery

- Packaging

- Pads & Accounts

- Personal Protection

- Clothing & Workwear

- Eye Protection

- Footwear

- Hand Protection

- Gloves – Cold Resistant

- Gloves – Cotton

- Gloves – Cowhide

- Gloves – Disposable

- Gloves – Extra Grip

- Gloves – Goatskin

- Gloves – Latex

- Gloves – Leather

- Gloves – Mixed Fibre

- Gloves – Nitrile

- Gloves – Polkadot

- Gloves – Polyurethane

- Gloves – PVC

- Gloves – Rigger

- Gloves – Stockinette

- Gloves – Terry Towelling

- Gloves – Vinyl

- Gloves – Welders Gauntlets

- Head & Face Protection

- Hearing Protection

- Knee & Elbow Pads

- Personal Protection Kits

- Respiratory Protection

- Piston & Valve Tools

- Power Tools

- Site Safety

- Spindle Nose & Workholding

- Steps & Access Equipment

- Storage & Handling

Blog

Relaunch Promotion

Product Showcase

Category: Adjustable Wrenches

Adjustable Wrenches

Showing 17–32 of 59 results

-

15″ SATIN-CHROME ADJUSTABLE WRENCHRead more

Yamoto Satin Finish Adjustable Wrenches

Slimline tapered parallel jaws for improved access into confined spaces with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Graduated laser etched jaws for fast repeatable jaw

setting and adjustment. Manufactured from âIâ beam section chrome vanadium steel for improved strength and rigidity, he jaws are heat treated for extended tool life. Corrosion-resistant satin finish. 22.5° offset head angle for positive torque control.Suitable for marine engineering, automotive, aerospace, agricultural maintenance and assembly applications.Conform to: ISO 6787-1982, ASME B.107.8M-1996, BS 6333-199405, DIN3117-1988, JIS B4604-1976.

Torque Ratings Conform to ISO 6787:1982. -

15″/380mm C/V ADJUSTABLESPANNERRead more

Senator Chrome Finish Adjustable Wrenches

Manufactured from âIâ beam section chrome vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished corrosion-resistant chrome finish. 22.5° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, aerospace, maintenance and assembly applications.

Torque Ratings Conform to: ISO 6787:1982.

-

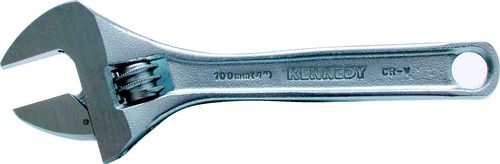

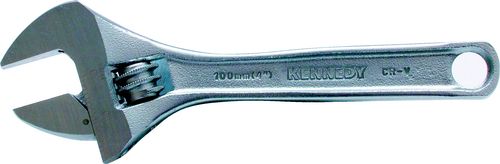

150mm/6″ CHROMED FINISH ADJUSTABLE WRENCHAdd to cart

Kenendy Adjustable Wrenches – Chrome Finish

Chrome Finish

Manufactured from high strength ‘I’ beam section chrome or phosphate vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished, corrosion-resistant finish. 15° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, agricultural, maintenance and assembly applications.Conforms to: ISO 6787-1982, ASME B.107.8M-1996, BS 6333-1995, DIN3117-1988, JIS B4604-1976.

-

150mm/6″ PHOSPHATE FINISH ADJUSTABLE WRENCHRead more

Kenendy Adjustable Wrenches – Phosphate Finish

Phosphate Finish

Manufactured from high strength ‘I’ beam section chrome or phosphate vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished corrosion-resistant finish. 15° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, agricultural, maintenance and assembly applications.Conforms to: ISO 6787-1982, ASME B.107.8M-1996, BS 6333-1995, DIN3117-1988, JIS B4604-1976.

-

150mm/6″ SOFT GRIP PHOSPHATE ADJUSTABLE WRENCHAdd to cart

Kennedy Cushion Grip Adjustable Wrenches

Drop forged chrome vanadium steel with phosphate anti-corrosion finish. Hardened parallel opening jaws are ground and polished, laser etched with metric graduations for rapid repeatable reference setting. The wide grooved profile of the opening mechanism and coarsely knurled adjusting screw ensures smooth adjustment. Slim head profile allows easy access, the contoured jaws improve grip when used on damaged misshaped fasteners. The unique geomatic cushion grip improves user comfort, is resistant to oil and grease to provide a slip free grip. Securely bonded to the I-beam handle sub frame to prevent the ingress of oil and dirt.

Conforms to: BS 6333: 1983, ANSI B107.8: 1977, DIN 3117, ASME B107.8: 1996. -

18″ CHROMED JAW AND KNURL KITRead more

Kennedy Service Kits for Adjustable Wrenches

Consisting of replacement jaw, knurl and pin.

-

18″ PHOSPHATE JAW AND KNURL KITRead more

Kennedy Service Kits for Adjustable Wrenches

Consisting of replacement jaw, knurl and pin.

-

18″/457mm C/V ADJUSTABLESPANNERRead more

Senator Chrome Finish Adjustable Wrenches

Manufactured from âIâ beam section chrome vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished corrosion-resistant chrome finish. 22.5° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, aerospace, maintenance and assembly applications.

Torque Ratings Conform to: ISO 6787:1982.

-

200mm/8″ CHROMED FINISH ADJUSTABLE WRENCHAdd to cart

Kenendy Adjustable Wrenches – Chrome Finish

Chrome Finish

Manufactured from high strength ‘I’ beam section chrome or phosphate vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished, corrosion-resistant finish. 15° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, agricultural, maintenance and assembly applications.Conforms to: ISO 6787-1982, ASME B.107.8M-1996, BS 6333-1995, DIN3117-1988, JIS B4604-1976.

-

200mm/8″ PHOSPHATE FINISH ADJUSTABLE WRENCHRead more

Kenendy Adjustable Wrenches – Phosphate Finish

Phosphate Finish

Manufactured from high strength ‘I’ beam section chrome or phosphate vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished corrosion-resistant finish. 15° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, agricultural, maintenance and assembly applications.Conforms to: ISO 6787-1982, ASME B.107.8M-1996, BS 6333-1995, DIN3117-1988, JIS B4604-1976.

-

200mm/8″ SOFT GRIP PHOSPHATE ADJUSTABLE WRENCHRead more

Kennedy Cushion Grip Adjustable Wrenches

Drop forged chrome vanadium steel with phosphate anti-corrosion finish. Hardened parallel opening jaws are ground and polished, laser etched with metric graduations for rapid repeatable reference setting. The wide grooved profile of the opening mechanism and coarsely knurled adjusting screw ensures smooth adjustment. Slim head profile allows easy access, the contoured jaws improve grip when used on damaged misshaped fasteners. The unique geomatic cushion grip improves user comfort, is resistant to oil and grease to provide a slip free grip. Securely bonded to the I-beam handle sub frame to prevent the ingress of oil and dirt.

Conforms to: BS 6333: 1983, ANSI B107.8: 1977, DIN 3117, ASME B107.8: 1996. -

230mm ADJUSTABLE GENERALPURPOSE WRENCHRead more

Senator Chromed Drop Forged General Purpose Wrench

Made from fully chrome plated drop forged steel. Jaw opening capacity 68mm. 90° sliding jaw. Overall length: 230mm.

-

24″ CHROMED JAW AND KNURL KITRead more

Kennedy Service Kits for Adjustable Wrenches

Consisting of replacement jaw, knurl and pin.

-

24″ PHOSPHATE JAW AND KNURL KITRead more

Kennedy Service Kits for Adjustable Wrenches

Consisting of replacement jaw, knurl and pin.

-

250mm/10″ CHROMED FINISHADJUSTABLE WRENCHAdd to cart

Kenendy Adjustable Wrenches – Chrome Finish

Chrome Finish

Manufactured from high strength ‘I’ beam section chrome or phosphate vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished, corrosion-resistant finish. 15° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, agricultural, maintenance and assembly applications.Conforms to: ISO 6787-1982, ASME B.107.8M-1996, BS 6333-1995, DIN3117-1988, JIS B4604-1976.

-

250mm/10″ PHOSPHATE FINISH ADJUSTABLE WRENCHAdd to cart

Kenendy Adjustable Wrenches – Phosphate Finish

Phosphate Finish

Manufactured from high strength ‘I’ beam section chrome or phosphate vanadium steel for improved strength and rigidity, the jaws are heat treated for extended tool life. High polished corrosion-resistant finish. 15° offset head angle for positive torque control. Slimline tapered jaws for improved access into confined spaces. Parallel jaws with smooth jaw adjustment and self-locking design prevents the jaws opening unintentionally even when under full load. Suitable for industrial engineering, automotive, agricultural, maintenance and assembly applications.Conforms to: ISO 6787-1982, ASME B.107.8M-1996, BS 6333-1995, DIN3117-1988, JIS B4604-1976.