Category

- Abrasives

- Adhesives & Sealants

- Automotive

- Bearings & Transmissions

- Cabinets & Racking

- Calipers & Gauges

- Catering Equipment & Supplies

- Cleaning & Hygiene

- Collets & Toolposts

- Computers & Accessories

- Counterboring & Spot Facing

- Cutting Tools

- Bandsaws & Hacksaws

- Countersinking

- Deburring

- Hole Making

- Milling

- Ball Nose

- Carbide B/N End Mills – Long Series

- Carbide B/N End Mills – Regular Series

- Carbide B/N End Mills – Short Series

- Carbide B/N Slot Drills – Long Series

- Carbide B/N Slot Drills – Regular Series

- HSS B/N Slot Drills – Long Series

- HSS B/N Slot Drills – Short Series

- HSS-Co. B/N Slot Drills – Long Series

- HSS-Co. B/N Slot Drills – Short Series

- Bore Milling

- End Mills

- Carbide Double Ended End Mills – Regular Series

- Carbide End Mills – Long Series

- Carbide End Mills – Regular Series

- Carbide End Mills – Short Series

- HSS End Mills – Long Series

- HSS End Mills – Short Series

- HSS-Co. End Mills – Long Series

- HSS-Co. End Mills – Regular Series

- HSS-E PM End Mills – Regular Series

- Indexable Bodies

- Key & Slot Cutters

- Milling Inserts

- Roughing/Ripper Cutters

- Slot Drills

- Carbide Slot Drills – Double Ended

- Carbide Slot Drills – Long Series

- Carbide Slot Drills – Regular Series

- Carbide Slot Drills – Short Series

- HSS Slot Drills – Long Series

- HSS Slot Drills – Short Series

- HSS-Co. Slot Drills – Long Series

- HSS-Co. Slot Drills – Regular Series

- HSS-Co. Slot Drills – Short Series

- Slot Drill Cutter Sets

- Special Geometry Cutters

- Throwaway Cutters

- Ball Nose

- Part off & Grooving

- Reamers

- Reference/Data Books

- Threading

- Die nuts

- Dies

- Indexable

- Tapping Hand

- BA ISO529 HSS-GT Taps

- BSF ISO529 HSS-GT Taps

- BSPF ISO529 HSS-GT Taps

- BSPT ISO529 HSS-GT Taps

- BSW ISO529 HSS-GT Taps

- Combination Drill/Taps

- Left Hand ISO529 HSS-GT Taps

- Metric Coarse ISO529 HSS-GT Taps

- Metric Fine ISO529 HSS-GT Taps

- Metric ISO529 HSS-GT Threading Sets

- NPSF ISO529 HSS-GT Taps

- NPT ISO529 HSS-GT Taps

- NPTF ISO529 HSS-GT Taps

- Tap Wrenches

- UNC ISO529 HSS-GT Taps

- UNF ISO529 HSS-GT Taps

- Tapping Production

- Thread Chasers

- Turning

- Display Material

- Fasteners

- Fluid & Water Control

- Fluid Power

- Furniture

- Hand Tools

- Building & Construction

- Carpenters & Joiners

- Auger; Forstner & Flat Bits

- Bradawls; Gimlets & Tacklifters

- Chalk Lines

- Hand Drills & Braces

- Hole Cutters

- Marking & Cutting Gauges

- Mitre Blocks & Bench Hooks

- Pincers

- Planes

- Saws – Coping; Fret & Flexisaws

- Saws – Gents; Dovetail & Tenon

- Saws – Hand & Mitre

- Squares; Rules & Bevels

- Surface Forming Tools

- Wood Chisels

- Wood Turning & Carving Tools

- Clamps

- Cutting & Sawing

- Cycle Tools

- Decorators

- Electrical

- Engineers Tools

- Gardeners & Contractors

- Keys & Drivers

- Measuring

- Non Sparking Tools

- Pliers & Grips

- Plumbing & Pipe Tools

- Riveters

- Screwdriver Bits

- Screwdrivers

- Screwdrivers – Cabinet Handle

- Screwdrivers – Electronics & Mini

- Screwdrivers – Fluted Handle

- Screwdrivers – Hi-Grip/Mechanics Style Handle

- Screwdrivers – Insulated Handle

- Screwdrivers – Offset/Double Ended

- Screwdrivers – Precision/Jewellers

- Screwdrivers – Protorq/Magnum Style Handle

- Screwdrivers – Spiral Ratchet/Yankee

- Sheet Metal Working

- Sockets (Hand)

- Sockets (Impact)

- Spanners & Wrenches

- Stencils & Engraving

- Striking Tools

- Tool Kits & Multi Tools

- Torque Tools

- Vices

- Lubricants & Chemicals

- Anti Seize Lubricants

- Chain; Drive & Rope Lubricants

- Corrosion Preventatives & Welders Anti-Spatter

- Food Industry Lubricants & Greases

- Greases

- Grinding Fluids

- Hot Dip Coatings

- Industrial Cleaners & Solvents

- Leak Detectors; Flawfinders & Freezer Sprays

- Lubricating and Penetrating Oils

- Marker Paints & Pens

- Metal Cutting Coolants

- Mould Release Agents

- Paints & Primers

- Tapping & Drilling Lubricants

- Water Displacing & Maintenance Oils

- Materials & Maintenance

- Measuring & Test Equipment

- Co-Ordinate Measuring Machines

- Electrical Measuring & Testing Equipment

- Environment Gauges

- Inspection Workholding

- Mechanical Gauges

- Non-Mechanical Gauges

- Optical Equipment

- SPC & Digital Readout Equipment

- Spring Calipers & Spring Dividers

- Surface/Hardness Testers

- Test Gauges & Accessories

- Weigh Scales

- Office Supplies & Stationery

- Packaging

- Pads & Accounts

- Personal Protection

- Clothing & Workwear

- Eye Protection

- Footwear

- Hand Protection

- Gloves – Cold Resistant

- Gloves – Cotton

- Gloves – Cowhide

- Gloves – Disposable

- Gloves – Extra Grip

- Gloves – Goatskin

- Gloves – Latex

- Gloves – Leather

- Gloves – Mixed Fibre

- Gloves – Nitrile

- Gloves – Polkadot

- Gloves – Polyurethane

- Gloves – PVC

- Gloves – Rigger

- Gloves – Stockinette

- Gloves – Terry Towelling

- Gloves – Vinyl

- Gloves – Welders Gauntlets

- Head & Face Protection

- Hearing Protection

- Knee & Elbow Pads

- Personal Protection Kits

- Respiratory Protection

- Piston & Valve Tools

- Power Tools

- Site Safety

- Spindle Nose & Workholding

- Steps & Access Equipment

- Storage & Handling

Archives: Products

Showing 22241–22256 of 23773 results

-

SC11a 32x40mm SCREW JACKRead more

Clamp Fixture Components: SC11A – Screw Jack

SC11A – Screw Jack

Material: Medium Carbon Steel.

Hardness: HRC 40.

Surface Finish: Black Oxide. -

SC11a 65x100mm SCREW JACKRead more

Clamp Fixture Components: SC11A – Screw Jack

SC11A – Screw Jack

Material: Medium Carbon Steel.

Hardness: HRC 40.

Surface Finish: Black Oxide. -

SC1210032 100x32x19mm M12 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC1215032 150x32x22mm M12 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC126428 64x28x12mm M12 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC1410031 100x32x19mm M14 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC1415032 150x32x22mm M14 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC146428 64x28x12mm M14 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC16110038 100x38x20mm M16 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC16115038 150x38x22mm M16 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC1630C INDEXIBLE SPOT DRILLRead more

Multi-Pro Spot Drills & Chamfer Mills – Uses C32 GUX Inserts

A spotting drill with all the advantages of indexable inserts – reduced tool maintenance time, increased performance, lower inventory cost and no regrinding requirements. The insert clamping method ensures accurate and secure location with quick change-over times. Multi-pro has a unique geometry which allows cutting over the centre line, using carbide, without chipping of the cutting edge. This versatile tool may be used to âspotâ holes prior to drilling, as a means to guide the drill and keep the hole straight, to keep size and accurately position, relative to the datum. NB. The 118° inclusive tool is recommended for âspottingâ prior to drilling with 118° point drills. Countersinks may be produced prior to drilling to provide a corner break on a drilled hole, a chamfer conforming to drawing specifications, a lead in for a subsequent tapping operation, or a full countersink to accommodate a screw head. Corner chamfers on edges, contours and bores can be machined as light de-burring operations or full depth chamfers. Multi-pro may be used to produce vee grooves for fluid channels, locations for round components and grip pattern or serrations on jaws and clamp pads.

-

SC1645C INDEXIBLE SPOT DRILLRp7.696.000Read more

Multi-Pro Spot Drills & Chamfer Mills – Uses C32 GUX Inserts

A spotting drill with all the advantages of indexable inserts – reduced tool maintenance time, increased performance, lower inventory cost and no regrinding requirements. The insert clamping method ensures accurate and secure location with quick change-over times. Multi-pro has a unique geometry which allows cutting over the centre line, using carbide, without chipping of the cutting edge. This versatile tool may be used to âspotâ holes prior to drilling, as a means to guide the drill and keep the hole straight, to keep size and accurately position, relative to the datum. NB. The 118° inclusive tool is recommended for âspottingâ prior to drilling with 118° point drills. Countersinks may be produced prior to drilling to provide a corner break on a drilled hole, a chamfer conforming to drawing specifications, a lead in for a subsequent tapping operation, or a full countersink to accommodate a screw head. Corner chamfers on edges, contours and bores can be machined as light de-burring operations or full depth chamfers. Multi-pro may be used to produce vee grooves for fluid channels, locations for round components and grip pattern or serrations on jaws and clamp pads.

-

SC166431 64x31x15mm M16 STEP CLAMPRead more

Atlas Step Clamp

Material: Medium Carbon Steel.

Hardness: HRC 32 – 38.

Surface Finish: Black Oxide. -

SC2-500C TRIKE FREE CONTACT CLEANER CO2 500mlRead more

Cleaner Spray

SC2-500C Electrical Contact Cleaner Spray – Trike-free

An effective solvent based cleaner. The product is formulated to remove oil, grease and carbon dust from electrical switch gear and electronic components. It is safe on most common plastic parts, but will attack lacquer finishes and coatings. If in doubt about suitability, trial the product on a scrap sample first before general application. The product is propelled from the aerosol by CO2 carbon dioxide gas (non-flammable). Electrical Switch Cleaner fluid is flammable. Always ensure power is switched off before applying this product to electrical equipment. -

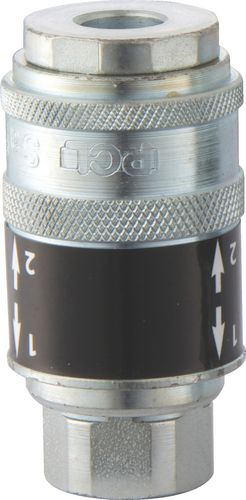

SC21CF 1/4″ BSPT SAFEFLOW FEMALE COUPLINGRead more

PCL XF Couplings

XF couplings and adaptors offers excellent flow characteristics providing the workshop with increased airflow and enhanced tool efficiency. Steel construction with corrosive resistant finish for longer life. The high flow rate – 130cfm at 100lbf/in², offers enhanced tool efficiency. Steel shoulder prevents accidental disconnection.

Nominal bore: 7.4mm.

Flow rate @ 6bar: 2200l/min @ 0.5bar p.d. Maximum working pressure: 35 bar. (508lbf/in²).

Temperature range: -40°C to 100°C. -

SC21CM 1/4″ BSPT SAFEFLOW MALE COUPLINGRead more

PCL XF Couplings

XF couplings and adaptors offers excellent flow characteristics providing the workshop with increased airflow and enhanced tool efficiency. Steel construction with corrosive resistant finish for longer life. The high flow rate – 130cfm at 100lbf/in², offers enhanced tool efficiency. Steel shoulder prevents accidental disconnection.

Nominal bore: 7.4mm.

Flow rate @ 6bar: 2200l/min @ 0.5bar p.d. Maximum working pressure: 35 bar. (508lbf/in²).

Temperature range: -40°C to 100°C.